Occupational lung diseases are a significant concern in many industries across the UK. These conditions, often resulting from prolonged exposure to harmful substances or hazardous working environments, can have devastating long-term effects on workers’ health. As an employer, it’s crucial to understand the risks, symptoms and preventative measures to protect your workforce.

What are occupational lung diseases?

These are a group of respiratory conditions caused – or exacerbated – by inhaling harmful substances in the workplace. These substances can include dust, fumes, gases and chemicals. Some common examples of occupational lung diseases include:

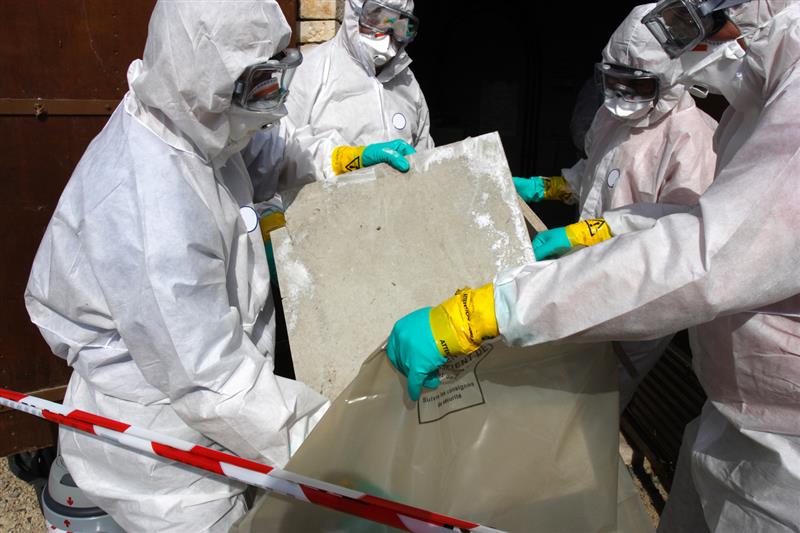

- Asbestosis: A condition caused by inhaling asbestos fibres, leading to scarring of the lungs and breathing difficulty.

- Chronic Obstructive Pulmonary Disease (COPD): Often linked to long-term exposure to harmful dust, fumes or gases, this disease makes it hard for individuals to breathe properly.

- Pneumoconiosis: A lung disease caused by inhaling dust particles, typically found in industries like mining or construction.

- Silicosis: Caused by inhaling fine silica dust, commonly found in industries like quarrying, stone cutting and construction.

- Asthma: Work-related asthma occurs when exposure to allergens or irritants at work triggers asthma-like symptoms or makes existing asthma worse.

The risks to workers

Workplace exposure to hazardous substances is the primary risk factor for developing occupational lung disease. These risks are often underestimated, but with the right knowledge and protective measures, they can be managed effectively. Key risks include:

- Dust: This includes mineral dust (such as asbestos or silica), as well as organic dust from wood or crops. These can irritate the lungs and lead to chronic respiratory diseases.

- Fumes and vapours: Fumes from welding, for instance, or vapours from chemicals used in manufacturing, can cause long-term damage to the lungs.

- Gases: Exposure to harmful gases like carbon monoxide, nitrogen dioxide or hydrogen sulphide can lead to severe respiratory problems, especially in confined spaces.

- Allergens: Certain workplaces, such as those involving agricultural or animal-based work, may expose employees to allergens that can trigger asthma or other respiratory conditions.

The legal responsibilities of employers

Under the Health and Safety at Work Act 1974 and other related regulations, employers have a legal duty to ensure the health, safety and welfare of their employees. This includes preventing occupational lung diseases by controlling exposure to hazardous substances. Specifically, employers must:

- Conduct thorough risk assessments to identify potential respiratory hazards in the workplace. This should include an evaluation of tasks, processes and substances that could lead to inhalation of harmful particles or gases.

- Implement control measures to minimise exposure to harmful substances. The Control of Substances Hazardous to Health (COSHH) Regulations 2002 provides a framework for controlling hazardous substances. This includes: Substituting harmful substances with safer alternatives where possible. Using engineering controls, such as ventilation systems, to reduce exposure.

- Providing personal protective equipment (PPE), such as respirators, where necessary. Ensure that employees are properly trained to recognise the symptoms of lung diseases and the risks associated with exposure to hazardous substances. This includes providing information on how to use PPE correctly and safely.

- Carry out regular health surveillance for workers who may be at risk of developing lung diseases. This includes routine medical checks to detect early signs of respiratory problems. Employees exposed to high-risk substances should have their lung function monitored regularly and any abnormalities should be investigated promptly.

- Maintain accurate records of risk assessments, control measures, training and health surveillance. These records not only help in monitoring safety standards but also ensure compliance with legal requirements.

Have clear emergency procedures in place in case of accidents or incidents that result in exposure to hazardous substances. This includes having first-aid measures available, as well as clear evacuation plans if necessary.

Prevention

Preventing occupational lung diseases is a key priority for employers. By taking the following steps, employers can significantly reduce the risk of their workers developing lung conditions:

- Substitution of hazardous materials: When possible, replace harmful substances with safer alternatives. For example, using water-based paints instead of solvent-based ones or switching to non-toxic chemicals in cleaning products can reduce exposure to harmful fumes and dust.

- Engineering controls: Effective ventilation systems, dust extraction equipment and enclosed work processes can significantly reduce workers’ exposure to harmful substances. In industries where workers are exposed to hazardous dusts or fumes, such systems should be a priority.

- Personal Protective Equipment (PPE): Ensure that workers are provided with the appropriate PPE, such as dust masks, respirators and protective clothing. PPE should be well-maintained and regularly replaced. Training workers on the proper use and care of PPE is essential.

- Workplace Design: Where possible, redesign the workplace to minimise exposure. For example, in construction, using mechanical systems for cutting or grinding rather than manual methods can reduce the amount of dust created.

- Regular monitoring: Implement ongoing air quality monitoring in the workplace, especially in high-risk environments. Monitoring will help identify any spikes in harmful substance concentrations and allow for quick corrective action.

- Encouraging safe practices: Encourage workers to adopt safe working practices, such as proper handling and disposal of hazardous substances. Providing a culture of safety, where employees are motivated to report issues and hazards, is also essential.

Remember – health surveillance is a legal requirement in specific circumstances when there is still some residual risk to worker’s health, despite the control measures you may have put in place.